The design of stator assemblies varies depending on the type of electric motor and its intended application. For example, some stators may have distributed windings, where individual wires are placed in slots around the core, while others may use concentrated windings, where each coil is concentrated around a single tooth of the core. Additionally, the number of poles in the stator assembly determines the motor's speed and performance characteristics. Motors with more poles generally operate at slower speeds but with higher torque, making them suitable for applications like industrial machinery and vehicles.

The motor stator assembly is a critical component in the functioning of electric motors. This overview provides an in-depth look at the stator assembly, highlighting its importance, components, materials, manufacturing processes, and emerging trends. By understanding these aspects, one can appreciate the role of the stator in ensuring efficient and reliable motor performance.

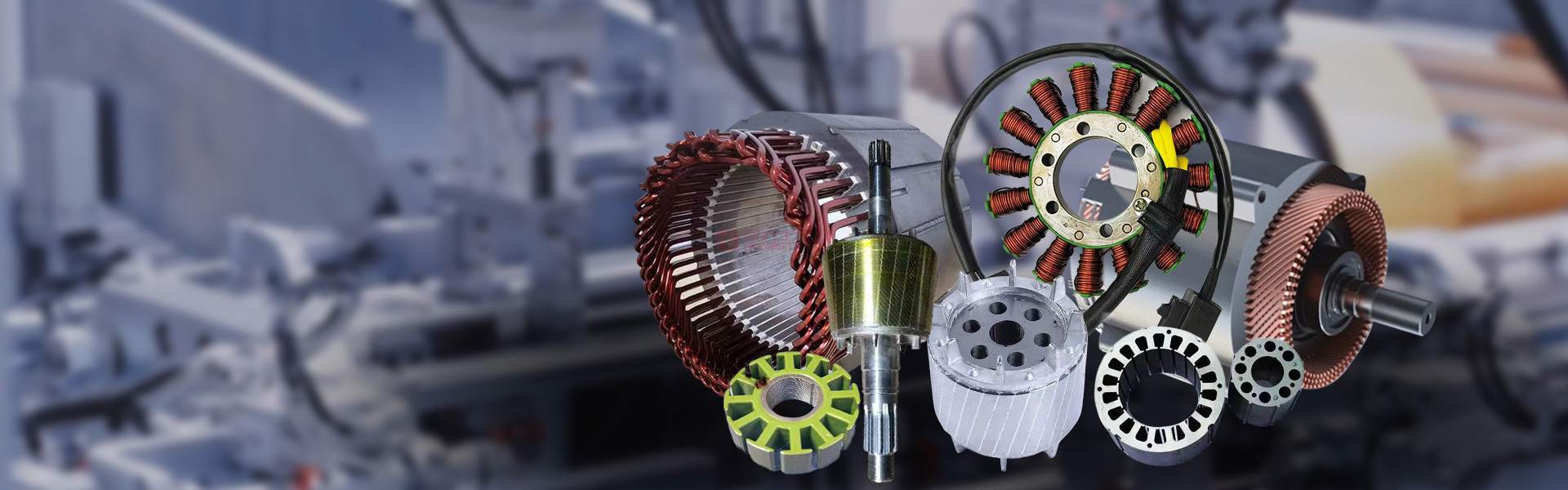

The stator core is made of laminated steel sheets to reduce eddy current losses. It provides the magnetic path for the stator windings and is crucial for efficient magnetic flux distribution.