Share

Aluminum Casting For Sale

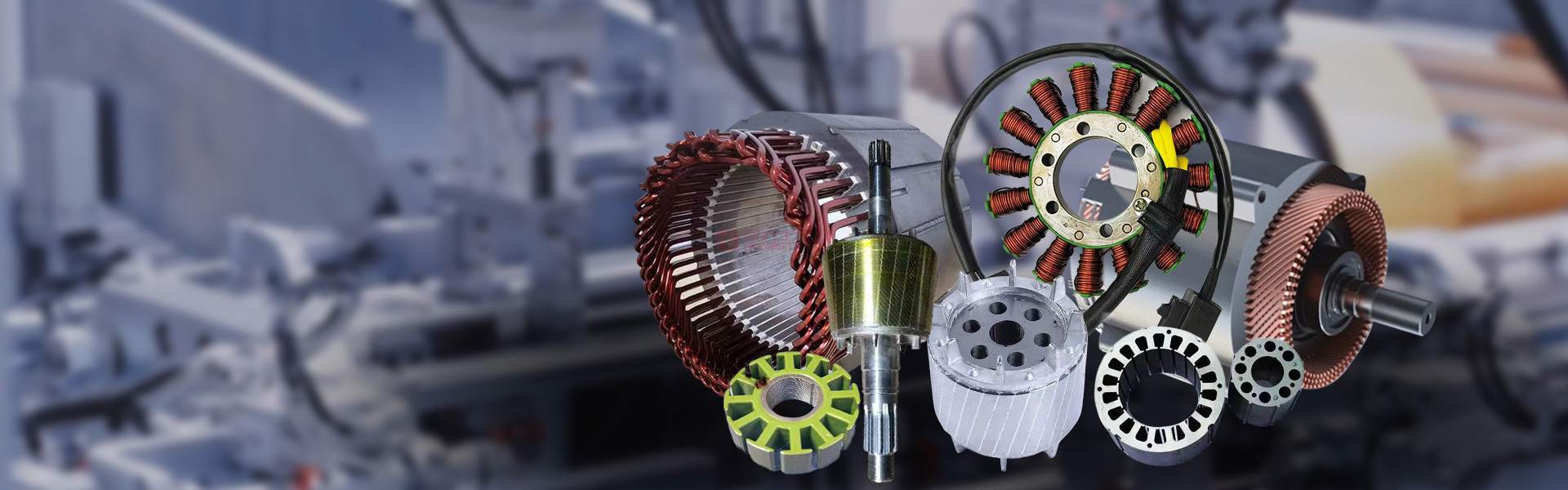

Summary: Main products: stator assembly, various motors, generators, water pumps, household appliances motors, permanent magnet motors, servo motors, etc.

Still thinking about it? Get samples first!Contact us!

View Category

Key words: stator assembly, motor

- Product Description

-

Several different methods of aluminum casting are used, each suited to specific applications and production requirements:

Sand Casting: This method involves creating a mold from a sand mixture, which is an economical and flexible option for producing large parts or small production runs. Sand casting is ideal for manufacturing engine blocks, pump housings, and other large components.

Die Casting: In die casting, molten aluminum is injected into a steel mold under high pressure. This method is well-suited for high-volume production of parts requiring tight tolerances and smooth surface finishes, such as automotive parts, electronic enclosures, and kitchenware.

Investment Casting: Also known as lost-wax casting, this process involves creating a wax model of the desired part, which is then coated with a ceramic material to form a mold. Once the ceramic mold is hardened, the wax is melted away, and molten aluminum is poured into the cavity. Investment casting is used for producing intricate and detailed parts, such as jewelry, turbine blades, and medical devices.

Permanent Mold Casting: This method uses reusable molds made from metal, typically steel or cast iron. Molten aluminum is poured into the mold, which allows for the production of high-quality parts with excellent dimensional accuracy and surface finish. Permanent mold casting is often used for manufacturing wheels, cylinder heads, and other automotive components.

Aluminum Casting For Sale

Still thinking about it? Get samples first!Contact us!

View Category

Key words: stator assembly, motor

Product inquiry

Note: Please leave your E-mail address and our professionals will contact you as soon as possible!