Share

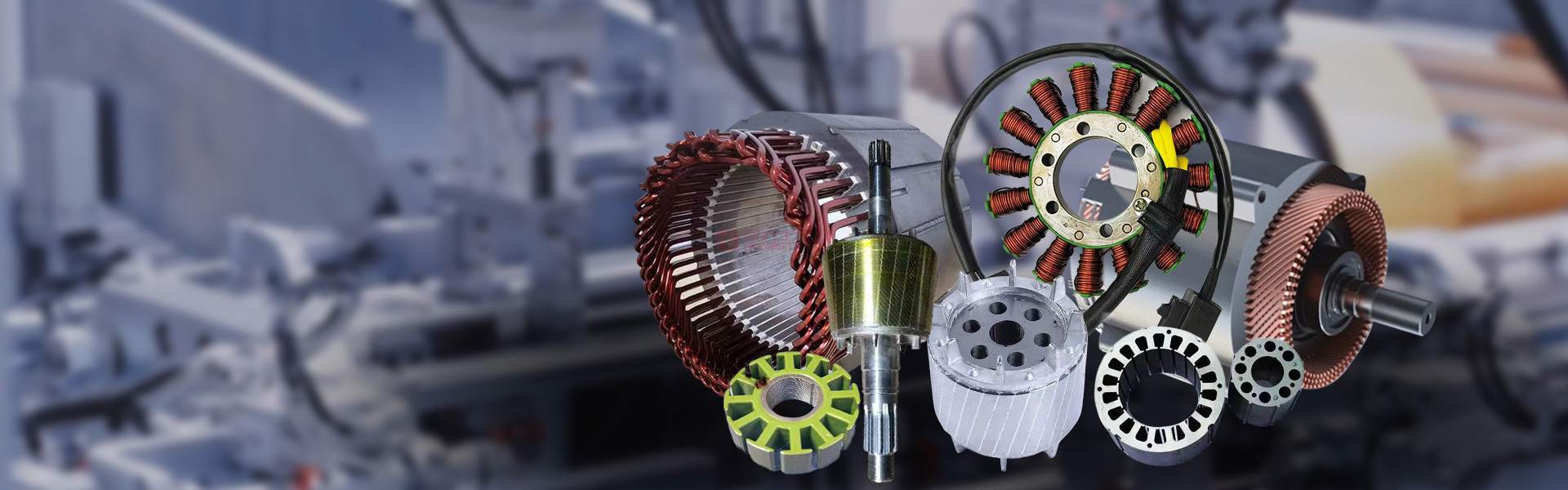

Low Price Motor Stator Assembly

Summary: Main products: stator assembly, various motors, generators, water pumps, household appliances motors, permanent magnet motors, servo motors, etc.

Still thinking about it? Get samples first!Contact us!

View Category

Key words: stator assembly, motor

- Product Description

-

The design of stator assemblies varies depending on the type of electric motor and its intended application. For example, some stators may have distributed windings, where individual wires are placed in slots around the core, while others may use concentrated windings, where each coil is concentrated around a single tooth of the core. Additionally, the number of poles in the stator assembly determines the motor's speed and performance characteristics. Motors with more poles generally operate at slower speeds but with higher torque, making them suitable for applications like industrial machinery and vehicles.

Stator assemblies also play a critical role in the efficiency and heat management of electric motors. The windings and core can generate significant heat during operation due to resistance and magnetic hysteresis losses. Proper cooling techniques, such as fan-cooling or liquid cooling systems, are essential to maintain optimal temperatures and prevent damage to the stator assembly over time.

In terms of manufacturing and materials selection, stator assemblies must be constructed using high-quality components to ensure longevity and reliability. The choice of conductor material for the windings affects the motor's efficiency and power output, with copper offering lower resistivity and better conductivity than aluminum. Additionally, the insulation material used to separate the windings must be able to withstand high temperatures and voltages without degrading over time.

In conclusion, motor stator assemblies are complex yet essential components of electric motors that generate the magnetic field necessary for motor operation. Their design, functionality, and materials selection directly impact the motor's performance characteristics, efficiency, and lifespan. As technology continues to advance and demand for efficient electric motors grows, the importance of well-designed and manufactured stator assemblies will only increase.

Low Price Motor Stator Assembly

Still thinking about it? Get samples first!Contact us!

View Category

Key words: stator assembly, motor

Product inquiry

Note: Please leave your E-mail address and our professionals will contact you as soon as possible!