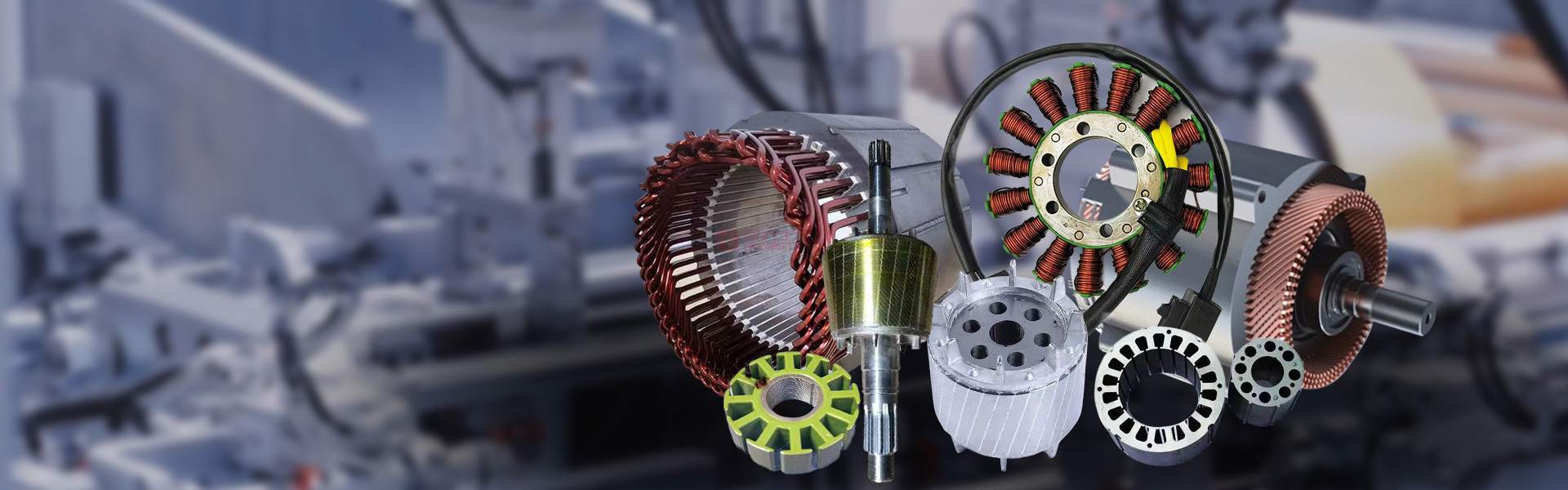

The Stator Assembly is a crucial component in various electrical machines, playing a vital role in converting electrical energy into mechanical energy or vice versa. Comprising the stationary part of the machine, it typically consists of a laminated core, windings, and insulation materials. The laminated core provides a magnetic path for the flux, reducing eddy current losses and increasing the efficiency of the assembly. The windings, usually made of copper or other conductive materials, carry the electrical current and generate the magnetic field necessary for the machine’s operation. Insulation materials ensure electrical isolation between the windings and the core, preventing short circuits and enhancing the reliability and safety of the stator assembly.

Large torsion double ball strong magnetic pure copper coil Using front and rear double ball low noise long life

DC brushless motor is a type of electric motor that operates without brushes. It uses electronic commutation to control the motor’s speed and torque. This makes it more efficient, reliable, and durable than traditional brushed motors. DC brushless motors are widely used in a variety of applications, including robotics, drones, automotive, and industrial machinery. They offer high power density, low noise, and precise control, making them ideal for demanding applications. With advancements in technology, DC brushless motors continue to evolve, providing even better performance and functionality.

When selecting a starting motor, it is important to consider factors such as engine size, type of vehicle, and intended use. For example, a high-performance sports car will require a more powerful starting motor than a small commuter car. Similarly, off-road vehicles and heavy machinery will need starting motors that can handle rough terrain and harsh environments.